Categories

- Blog (116)

- Valve Manufacturers (15)

This is a type of plug valve designed with a half plug. This type of valve is suitable for use in applications that need minimum friction and high seat forces from the open to the closing position. Eccentric plug valves are used in a variety of applications such as air, slurries, sludge, and clean and dirty water, among others. Eccentric plug valve manufacturers design these valves as modifications of the ball or cone valves. These valves are designed such that it is only half of the cone or ball used to close the fluid flow. When the eccentric plug valve is in the fully open position, its plug is made to be out of the fluid flow and recessed into the body. The eccentric plug rotation into the seat results in a motion like that of a mechanical cam. This helps the eccentric plug valve to force the plug against the seating surface for tight shut-off. Such design helps these valves to work well in slurry and sludge applications. When the valve is opened, fluid flows through the hollow valve passage. Eccentric plug valves employ simple and inexpensive design. Eccentric plug valves are either manual or actuated depending on the type of application and customer’s preferences.

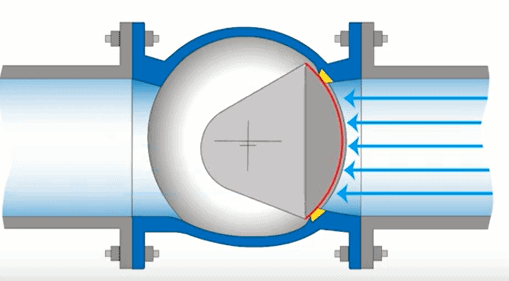

Figure: Eccentric plug valve.

This is the main part of an eccentric plug valve which is used to house all internal parts. The body is made of strong metallic materials like stainless steel, carbon steel, cast iron, and ductile iron among others. The use of such strong metallic materials helps to make the valve body strong to withstand fluid pressure. The valve body also contains the valve ports where fluid flows into and out of the valve.

The actuator is a component used to provide the force needed to open and close the eccentric plug valve. The actuator is used for automatic or semi-automatic eccentric plug valves. Eccentric plug valve manufacturers also design these valves for manual use in which the valve has a handwheel where the valve operator applies torque to open or close the fluid flow.

The stem is a component of an eccentric plug valve that connects the actuator/handwheel and the valve plug. The Stem is responsible for transmitting the force applied on the handwheel to the plug so that the plug can make a quarter turn and thus open or close fluid flow. The stem is made with threads allowing it to rotate.

This is a component of an eccentric plug valve which is placed between the valve body and the plug to prevent fluid leakage when the valve is closed. The seat also serves as the seating surface where the valve plug rests when it closes. Eccentric plug valve manufacturer design the seat with different materials making the valve suitable for use at different temperature levels.

The gasket is a component placed between the mating surfaces of the valve and pipe to enhance a tight seal free from fluid leakage. The type of material used to make the gasket determines the area of application and temperature level.

This is a component used in an eccentric plug valve that helps to prevent fluid leakage between the valve stem and the top cover.

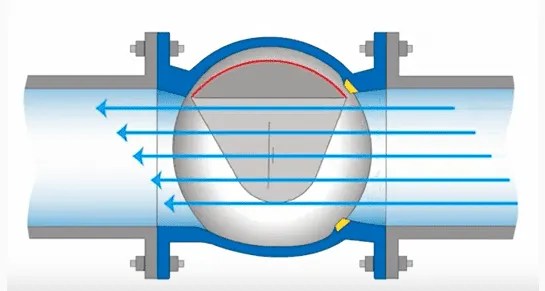

An eccentric plug valve works by rotating the plug for a 90o degree turn. This quarter turn helps to either close or open fluid flow. To open an eccentric plug valve, the handwheel is rotated for 90o degrees in the anticlockwise direction. This makes the plug make a quarter turn rotation and thus leaving the fluid passage open which then allows fluid flow through the eccentric plug valve. The fluid keeps flowing through the valve as long as the plug is not forced to seat back in its seating position. To close the eccentric plug valve, the handle or handwheel is rotated in the clockwise direction for a quarter turn. This forces the plug to return to the seating position in which it blocks the fluid passageway ensuring zero fluid flow. For throttling, the handwheel is rotated for a 45o degree angle which makes the plug open slightly allowing some amount of fluid flow. However, the throttling process causes a high-pressure drop and thus low efficiency.

Figure: Working of an eccentric plug valve open valve (left) and closed valve (right).

This is an eccentric plug valve that is designed with threads on the valve ports for connection to the pipe. Threaded-end eccentric plug valve manufacturers design these valves for use in medium pressure applications. These valves are small in size compared to the bolted type. Eccentric plug valves are designed with either male or female threads. A valve with male threads is connected to a pipe with female threads and vice versa. Threaded end eccentric plug valves are smaller in size and light in weight compared to the flanged or bolted type. These valves can be opened for cleaning, repair, and maintenance as necessary.

This is an eccentric plug valve that is designed with flanges at both ends of the ports. The valve and pipe are connected using bolts and nuts. The pipe and valve have same sized flanges. The flanges of both valves and pipes have holes where the bolts are inserted to hold the valve and pipe together. Eccentric plug valve manufacturers design this type of valve for use where there is high pressure and where installation space is not limited. These valves can be used in different ranges of temperature depending on the materials used to make internal parts like the plug, seat, rings, and gaskets. Flanged-end eccentric plug valves are free from fluid leakage due to their high strength and tight seals enhanced by use several bolts and nuts. Flanged-end eccentric plug valves have the disadvantage of being heavy relative to other valve types. The high weight arises from the use of bolts and nuts and flanges that add weight to the other parts of the valve.

This is an eccentric plug valve that is connected to the pipe by the welding method. The welding method means that the valve and the pipe are welded together. This method is very reliable as it guarantees zero fluid leakage. Welded-end eccentric plug valves are suitable for use in high-pressure applications as it ensures no leakage. These valves can also be used in high-temperature applications to ensure no steam leakage. Welded end eccentric plug valve manufacturers recommend use of these valves in hazardous applications such as in acids and flammable or very hot products. The welding method ensures that the hazardous fluids cannot leak ensuring there are no damages to the environment or injury to the valve operator. Welded end eccentric plug valves cannot be repaired or cleaned while in the field due to the weld connecting element. These valves are recommended for use in applications where cleaning or repair of the valve will not be done often.

Eccentric plug valve manufacturers design these valves to work in different applications ranging from corrosive, and viscous to non-corrosive and low viscosity fluids. Using the valve for the right fluid or media as recommended by the eccentric plug valve manufacturer helps to enhance service life and reduce the cost of repair and maintenance.

Eccentric plug valve manufacturers design a valve for use at a specific pressure and velocity. Using the valve for very high pressure than recommended may cause fluid leakage through valve connections. Also, very high fluid velocity causes vibrations or loud noise than normal. Thus the fluid pressure and velocity should match the values recommended by the eccentric plug valve manufacturer.

Eccentric plug valve manufacturers make these valves with different materials that can withstand different levels of temperatures. Some materials like rubber and plastic are used to make components like seats and rings that can withstand low temperatures below 60 oC. Very high temperatures need an eccentric plug valve in which internal parts are made of metallic materials like steel, brass, and bronze among others. Using the valve for the wrong temperature range can cause damage to internal parts or may cause the fluid to react with the valve components and thus causing damage.

An eccentric plug valve is a type of valve used to open and close fluid flow in different applications. Eccentric plug valve manufacturers design this type of valve with a half plug of ball or cone shape. When the valve is in its fully closed position, the half plug moves out of the fluid flow path and it gets recessed into the body. When the valve is opened fluid flows through the valve via a hollow passage. To close fluid flow through an eccentric plug valve, the handwheel is rotated in the clockwise direction for a quarter turn forcing the plug to rest on the seating surface and thus preventing fluid flow.