Categories

- Blog (116)

- Valve Manufacturers (15)

A double check valve is a type of valve that is used to prevent the backflow of fluid in water supply systems. Preventing the backflow of water helps to prevent contamination. A double check valve is made up of two check valves that are assembled in series. One of the check valves works even when the other one is jammed wide open. The closing element of one of the valves reduces pressure difference across the other which allows a more reliable seal and avoids minor leakage. However, this type of valve is not suitable for use in high hazardous applications. The double check valve is installed on pipes supplying water for garden irrigation, industrial use, fire suppression, and combi-boiler where there are risks of backflow contamination. A double check valve is a simple, reliable, and robust one-way valve. This valve uses gravity or a spring-loaded diaphragm or plunger to open fluid flow in one direction. Double check valve manufacturers design these valves to ensure that when the inlet pressure is more than the outlet pressure the valve opens and fluid flows in one direction only. From the perspective of efficiency, the pressure difference across the two check valves allows them to seat more effectively thus enhancing system efficacy. Some double check valve have a dual shutoff valve used to enhance efficiency further by allowing either section of the circuit to be isolated if it becomes necessary. Such dual shutoff valves in a double check valve are found in large industrial double check valves. Double-check valves for domestic use are more simple and smaller in size and they are of in-line designs or they are included in standard faucets.

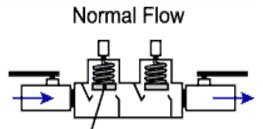

Figure: Double check valve.

A double check valve operates on the principle of differential pressure. A double check valve opens when the cracking pressure and upstream pressure are equal. At the instance the valve is opened, fluid start flowing through the double check valve. When the upstream pressure becomes less than the cracking pressure, the fluid tries to reverse the direction of flow from the discharge side to the inlet side. At this instance, the valve through its closing discs shuts off the fluid flow and thus prevents flow from reversing. Double-check valve manufacturers design these valves such that gravity or spring force is used to help in shutting the valve. The valve has a label on its body showing the direction of fluid flow. Double-check valves are superb solutions to potential problems that can threaten human life. These valves are simple in design, have high efficiency, excellent performance, and have low cost.

Figure: working of a double check valve; left side valve open during normal fluid flow; right side valve closed when fluid attempts to reverse flow direction.

These are double-checked valves that are made of stainless steel material. In this type of valve, the stainless steel material is preferred because of its high strength and resistance to corrosion, and high melting point. Double-check valve manufacturers make this valve for use in high and low-temperature and in low and high-pressure applications. The low-temperature applications have temperatures below 60oC. Such temperature can distort plastic material so before purchasing the double check valve ensure it can withstand the temperature where it will be installed. The low-temperature valves can have the seat made of plastic or rubber material and these are known as soft seated double check valves. The stainless steel material is used to make components like the body and disc.

Figure: Stainless steel double check valve.

This is a double-check valve that is made of brass material. This valve is suitable for use in consumable products such as water. Having a brass body and disc enhances valve strength against pressure and temperatures which may cause fluid leakage. Brass double check valves are easy to work with since brass material is softer relative to other materials like stainless steel which makes the valve sealing easier. These valves can be used in a wide range of temperatures that is -10 oC to 85 oC.

Figure: Brass double check valve.

PVC stands for polyvinyl chloride. This is a plastic material used to make a double check valve meant for use in low-temperature and low-pressure applications. Advantages of using PVC double check valves are sturdiness, lightweight, abrasion resistance, corrosion resistance, durability, and high resilience. These valves are easy to install. However, PVC double-check valves are not suitable for use in high-temperature applications because they can melt down or get damaged.

Figure: PVC double check valve.

A double check valve is a type of valve used to prevent backflow of water meant to ensure freshwater is not contaminated. The valve is made by connecting two check valves in series. Double-check valve manufacturers design these valves based on pressure difference principle. Using this principle when the inlet pressure exceeds the outlet pressure the valve opens. As such, fluid flows in one direction only. Any second the fluid attempts to flow backward due to low pressure the double check valve closes immediately. Double-check valves use a spring-loaded diaphragm or gravity or plunger to open for fluid to flow in one direction.

There are various types of double check valves which include PVC double check valves, stainless steel double check valves, and brass double check valves. Double-check valves are used in different applications such as irrigation, fire protection systems, commercial water tanks, household water systems, and mixed boilers among others. Advantages of using double check valves are light in weight, small in size, durable, cheaper relative to other check valves, zero fluid leakage, no reverse fluid flow, ability to maintain pressure, low-pressure drop, and simple and robust design. However, double check valves are small in size for handling small flow rates. These valves are can only allow fluid to flow in one direction and they are not suitable for use in pulsation systems.